Desktop Metal

P1

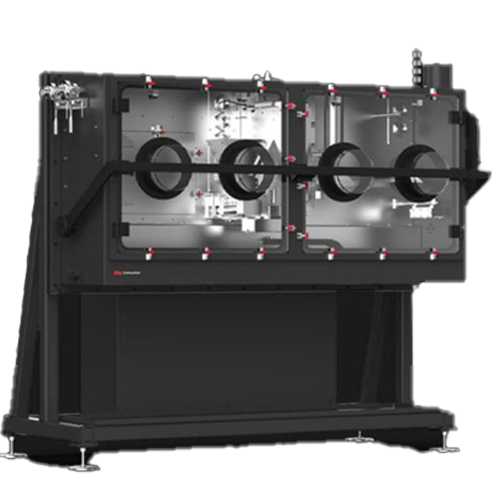

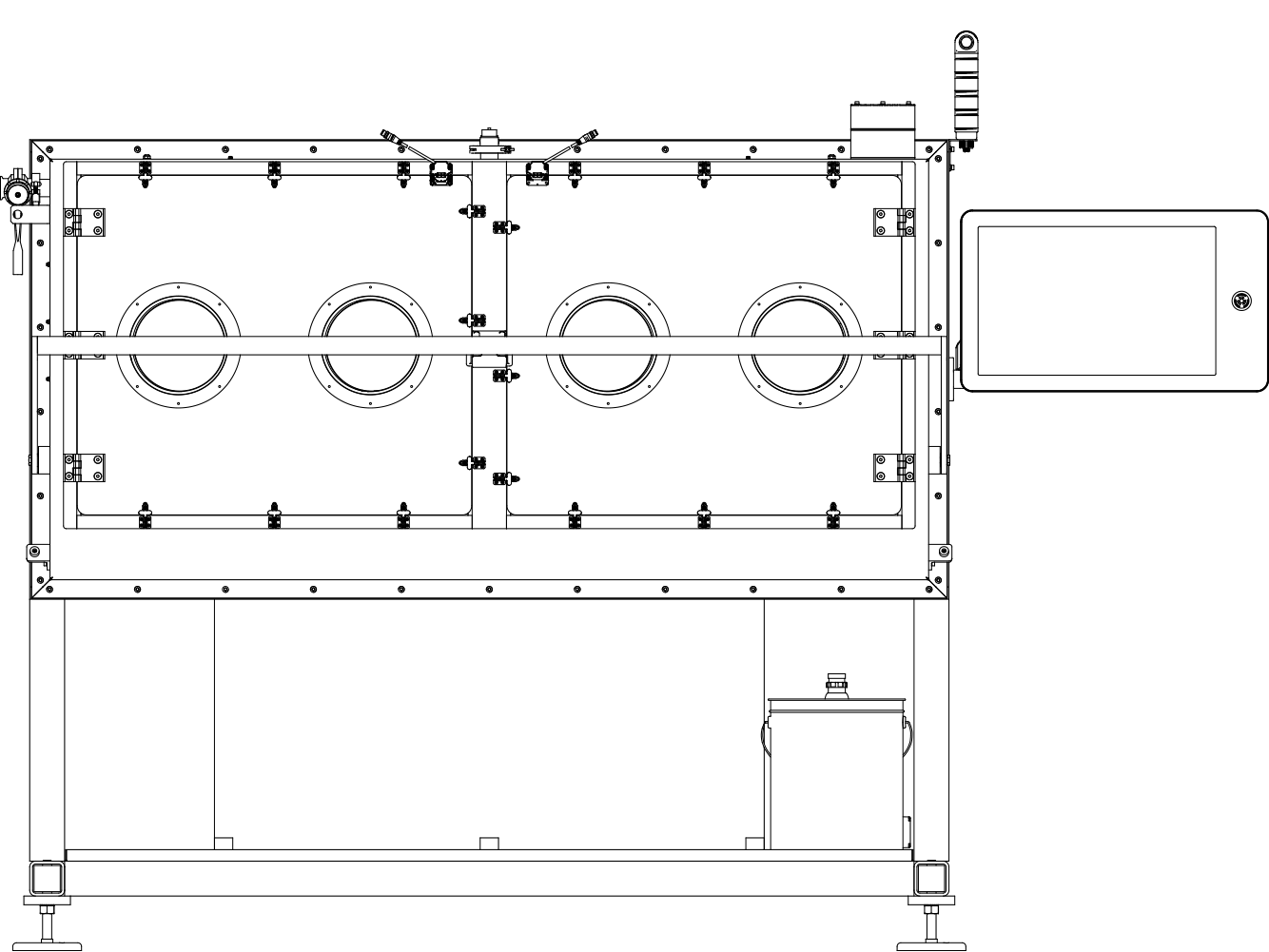

Designed to bridge the gap between bench top development and mass production, the P-1 offers the same excellent part quality as the P-50 with enhanced process flexibility. Featuring a state-of-the-art print bar with native 1200 dpi, an inert processing environment, and Desktop Metal's patent-pending Single Pass Jetting technology, the P-1 supports non-reactive and reactive materials at speeds more than 10 times those of laser powder bed fusion technologies⁴ and is capable of printing multiple builds per shift and direct process transfers to the P-50.