Desktop Metal

Desktop Metal has helped to reshape the Additive Manufacturing industry as the world’s leader in binder jet 3D printing. Desktop Metal has paired 3D printing technologies view as truly production capable with performance materials and select applications and technologies to help drive the next generation of additive.

Desktop Metal has achieved this by increasing speeds and reducing costs that compete with conventional CNC machining, as well as new levels of uptime and reliability in 3D printing. 3D metal printing systems include DM’s Studio System, Shop System, X Series and Product System.

Shop System

Turkey for Machine Shops

The world’s first metal binder jetting system designed for CNC machine shops and job shops. Job shop owners can now leverage affordable, high-quality binder jetting technology to 3D print end-user metal parts with unparalleled speed, print quality, and productivity

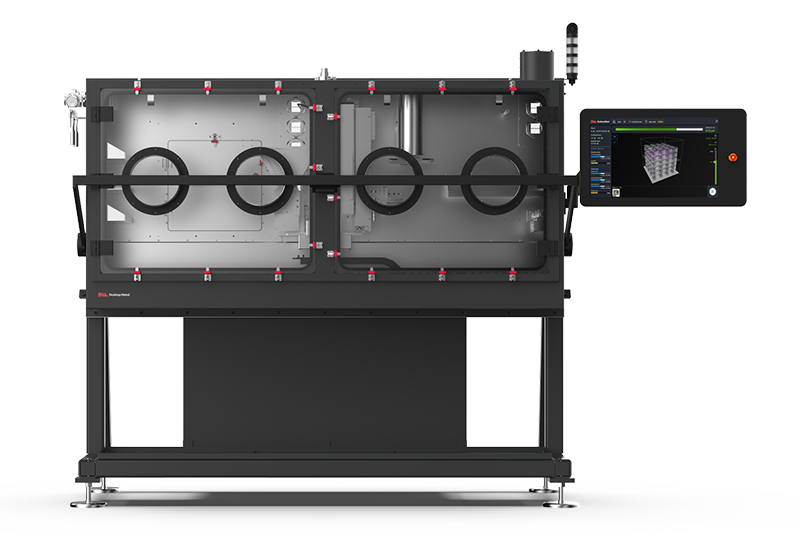

Studio System™ 2

Office Friendly, Shop Floor Strong

Office-friendly metal 3D printing solution for rapid prototyping in the engineering lap, or out on the shop floor alongside CNC machine tools. 3D print metal parts in just 2 steps — Print. Sinter.

Available Now.

Production System

X-Series

The X-Series family of scalable 3D printers — the InnoventX™, X25Pro™ and X160Pro™ — feature industrial piezoelectric printheads and patented Triple ACT advanced compaction technology, which dispenses, spreads, and compacts ultra-fine powders with tight parameter controls.