Desktop Metal

Production System

- The Production System™ delivers the speed, quality and cost-per-part needed for metal 3D printing to compete with traditional CNC machining techniques

- The Production System™ offers robust repeatability, through anti-ballistics technology, print bar redundancy and live optical print bed inspection. Meaning you can print with confidence

- 3D print customer-ready parts with densities up to or exceeding 99% without the need for infill or a solvent debind step. With properties similar to castings, Production System™ parts are suitable for demanding applications where strength is critical

- Proprietary constant wave spreading technology maintains a consistent powder wave in front of the compaction roller during printing, enhancing density uniformity across the powder bed. The result is greater consistency across parts within each build and from build-to-build

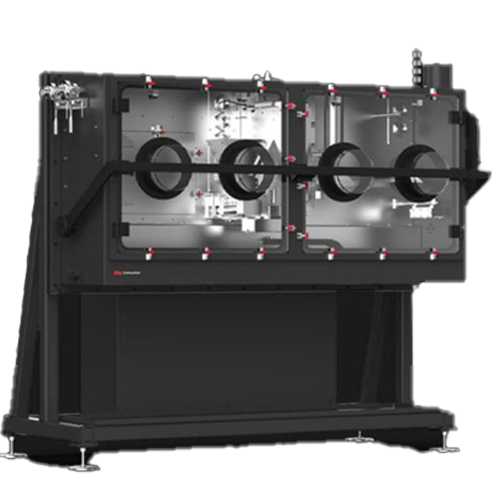

P1

Designed to bridge the gap between bench top development and mass production, the P-1 offers the same excellent part quality as the P-50 with enhanced process flexibility. Featuring a state-of-the-art print bar with native 1200 dpi, an inert processing environment, and Desktop Metal's patent-pending Single Pass Jetting technology, the P-1 supports non-reactive and reactive materials at speeds more than 10 times those of laser powder bed fusion technologies⁴ and is capable of printing multiple builds per shift and direct process transfers to the P-50.

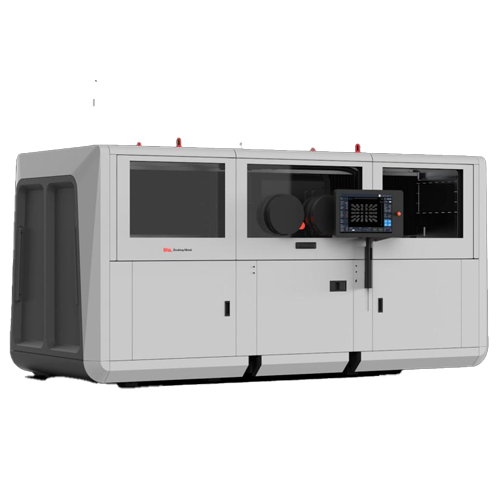

P50

Designed to be the fastest way to 3D print metal parts at-scale, the P-50 leverages Desktop Metal’s patent-pending Single Pass Jetting technology and bi-directional printing to achieve speeds up to 100 times those of laser powder bed fusion technologies⁴, producing parts in volumes and at costs competitive with conventional mass production techniques. Featuring a state-of-the-art print bar with native 1200 dpi, an inert processing environment, and constant wave spreading for print bed uniformity, the P-50 offers the quality, reliability, and economics required for high-volume, end-use applications.