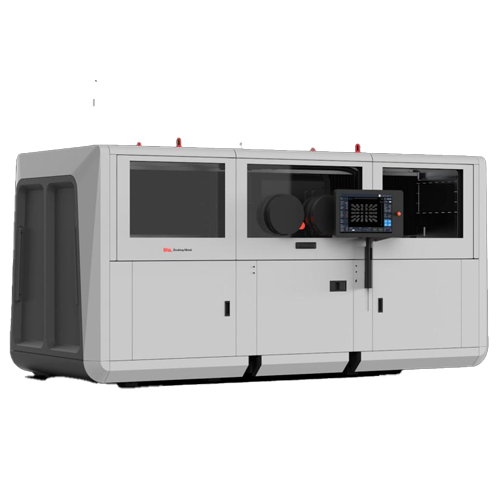

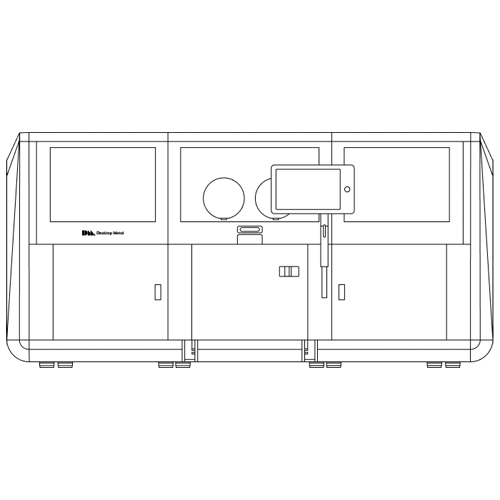

Desktop Metal

P50

The most anticipated 3D printer in additive manufacturing history is here. The P-50 is paving the way for mass-production of metal end-use parts with breakthrough. Additive Manufacturing 2.0 technology that

delivers new value for manufacturers. Join us for a 60 minute webinar to learn how Single-Pass Jetting (SPJ) technology delivers the speed and throughput necessary to compete with traditional manufacturing while also offering the benefits you'd expect in AM 2.0 technology, from reduced waste and consolidated part assemblies to lightweight part designs, de-risked supply chains and more.