Desktop Metal

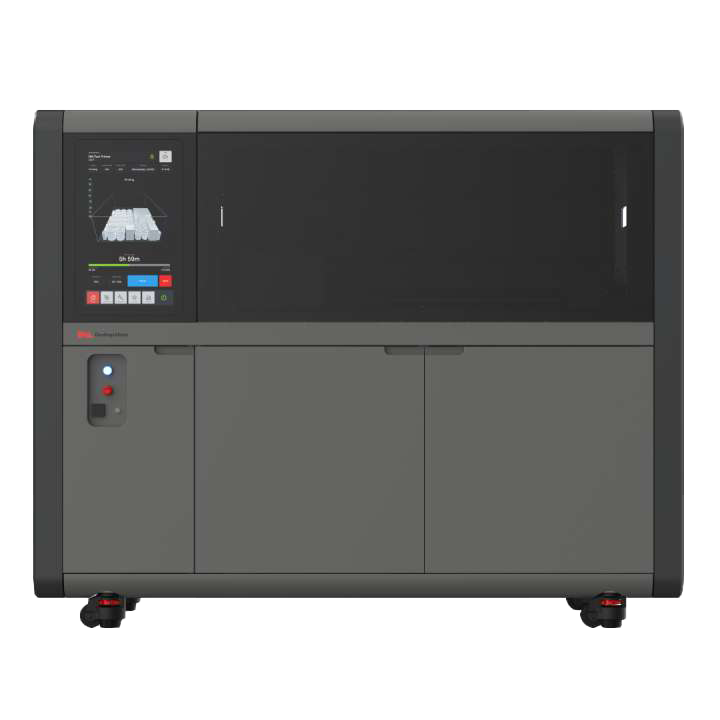

Shop System

The world’s first metal binder jetting system designed to bring metal 3D printing to machine shops. In addition to the turnkey standard system, Desktop Metal also offers the Shop System™+ and Shop System™ Pro packages for added flexibility, functionality, and value.

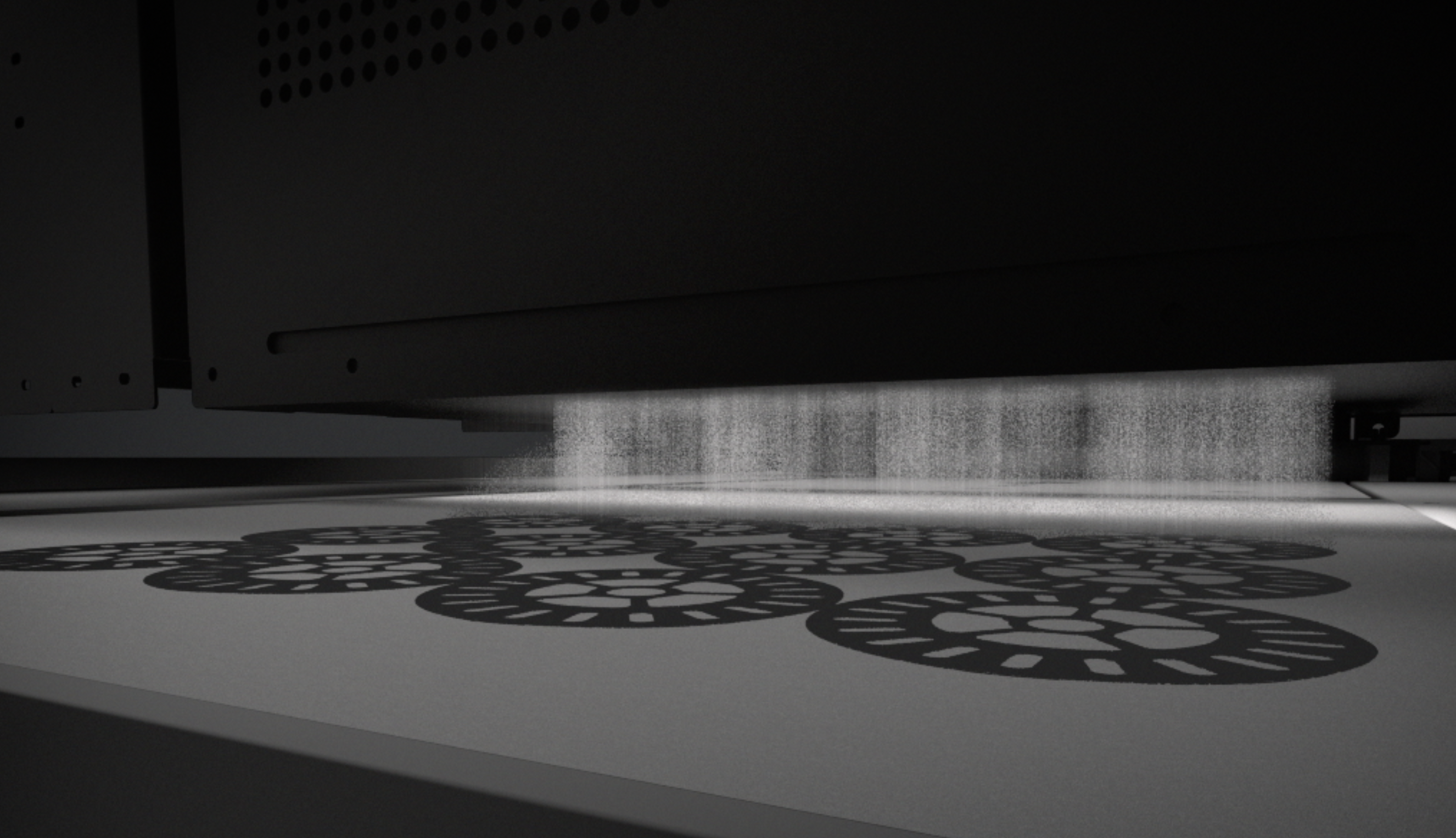

Printer

The Shop System™ printer features the most advanced printhead on the market with over 70,000 nozzles jetting 1.2pL droplets at nearly 10 kHZ to achieve high resolution, 3D printed parts at a fraction of the cost of laser-based systems.¹

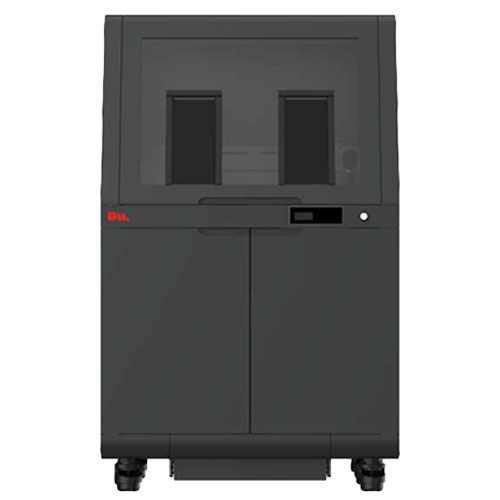

Powder Station

With easy access portholes, a hand-held air pick, built-in powder sieving and recycling, and a vacuum port for easy powder maintenance, the powder station provides closed-loop powder management and recycling.

Drying Oven

After printing, the build box containing the printed parts is placed into a crosslink oven. Crosslinking is a thermal cure process that gives printed parts in the green state additional strength before

depowdering.

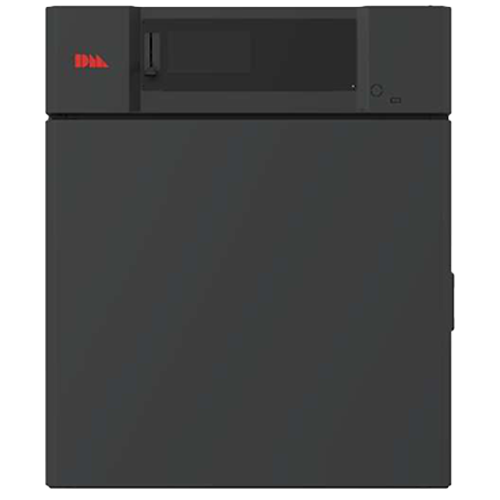

Furnace

The Shop System™ furnace is a shop-safe high-temp sintering oven built for cost-effective high throughput of 3D printed parts. Featuring external gas hookup and adjustable shelving, the furnace easily and affordably scales to mid-volume manufacturing.