Stratasys

Origin® One

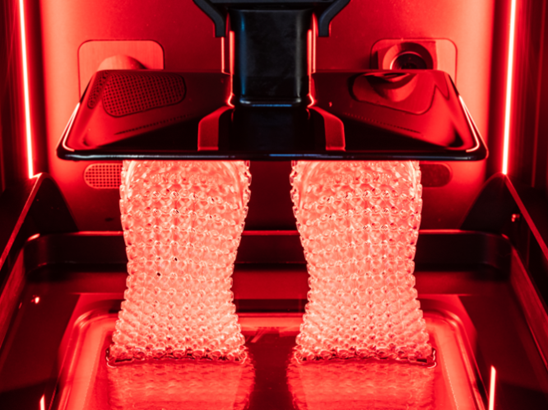

An evolution of digital light processing (DLP®), Programmable Photopolymerization technology (P3™) powers the Origin One. The tightly synchronized print process includes pneumatic controls to reduce pull forces during the print process, resulting in exceptional surface quality, without sacrificing speed or isotropy. It explains why Origin One is the only DLP printer (or any desktop resin printers like LCD actually) that successfully prints the widest range of geometry in resin, from large cross section bulky parts, parts printed directly on the platform, to the finest of features with less support.

How it works:

Technology

What is P3 DLP 3D Printing?

P3™, Programmable PhotoPolymerization, is an evolution of Digital Light Processing 3D printing. During the printing process light, temperature, pull forces and pneumatics are tightly controlled, resulting in repeatable injection-molding-like part quality and surface finish with high accuracy and tight tolerances. In combination with the broad range of performance materials, it enables functional prototyping and end-use applications across the widest range of geometries - from large bulky parts directly on the platform to the finest of features.

P3™, Programmable PhotoPolymerization, is an evolution of Digital Light Processing 3D printing. During the printing process light, temperature, pull forces and pneumatics are tightly controlled, resulting in repeatable injection-molding-like part quality and surface finish with high accuracy and tight tolerances. In combination with the broad range of performance materials, it enables functional prototyping and end-use applications across the widest range of geometries - from large bulky parts directly on the platform to the finest of features.

What is Digital Light Processing 3D Printing?

Digital Light Processing 3D printing uses a digital projector to cure photopolymer resins, resulting in repeatable high accurate parts with excellent resolution and constant quality. DLP 3D printing has higher irradiance than LCD and similar resin printing, parts with better mechanical properties (using the same material) and requiring fewer supports, even when printing overhangs, bridges, islands and large cross-sections (bulky parts).